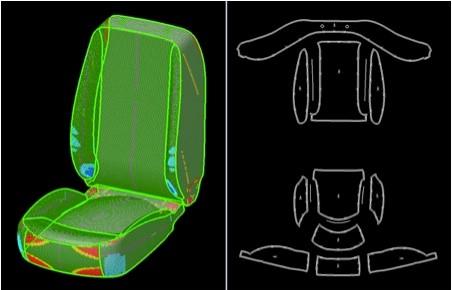

Loose Fit Dress Covers

Loose-fit aircraft seat covers ruled the airline world for many decades. Starting with fabrics and leathers, many airlines today still fly with a loose-fit cover. The majority of airlines flying with a loose-fit aircraft seat cover are short-haul or low-cost carriers. The price for manufacturing is typically lower than a laminated cover, and upkeep can be easier.

Contact Us